Navigating the Digital Transformation Journey: A Guide for Construction Professionals

BLOG The construction industry, long tethered to traditional methods, is

Have you been on site when there are issues with what’s been installed vs the design? If this happens to you far too often, then this article is for you. Problematic site designs cause delays and miscommunication between the design and site team. These disruptions can be avoided by incorporating the right Geospatial technological advances in your project.

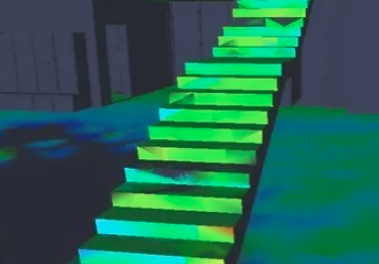

3D Laser Scanning technology has taken off in the design business, but it is underused in the construction sector. 3D Laser Scanning offers many advantages for enhancing the cost-effectiveness of your construction project from the Planning, Building and Operational stages.

Manual labour can be error-prone and Laser Scanning will increase that precision. Scanning minimises the requirement for frequent site visits as all the data can be viewed and analysed remotely.

3D Laser Scanning aids in enhancing cooperation and collaboration on a project site, leading to quicker and better overall decision-making. Better cooperation will improve project team relationships, communication, and aid in achieving the project’s ultimate objective.

At GagaMuller Group we use simple, non-destructive Laser Scanning to get accurate site conditions. Trade teams then depend on these scans to develop coordinated and precise building project plans. Using up-to-date site data allows the production of components off-site assuring accurate installs when brought to the site.

3D Laser Scanning allows for the collection of the most precise building documentation conceivable. 3D Laser Scanning captures minute details to provide a considerably more realistic representation of the structure. This method is much more reliable than the traditional technique of measuring tape and sketchpad data collection. Accurate 3D scan data offers builders with permanent records they can access in the future.

Using obsolete measuring methods, such as a tape measure, may require the placement of four to six field employees in risky conditions and prolong their stay on-site, hence increasing the risk of harm. Scanning in 3D eliminates the need for scaffolding and ladders. One laser scanner can precisely measure high ceilings and ducting that are inaccessible to humans.

Despite the construction industry’s reluctance to accept new technologies, Laser Scanning is rapidly becoming the standard on building sites due to the advantages outlined above.

Laser scanning cuts the time required to measure building sites by as much as half, it is a quality enhancement and leads to cost savings.

Scheduled scanning of your site during construction provides an accurate 3D point cloud overlay for visibility on your installation vs the construction schedule. It verifies your building is installed as per the design, avoiding large amounts of rework and protection against claims and delays from the site.

If you’d like further information about the 3D Laser Scanning services we offer at GagaMuller, get in touch.

BLOG The construction industry, long tethered to traditional methods, is

BLOG The construction industry is notorious for being capital-intensive and

BLOG This blog is going to discuss how you can

Apply Now

Apply Now